↓

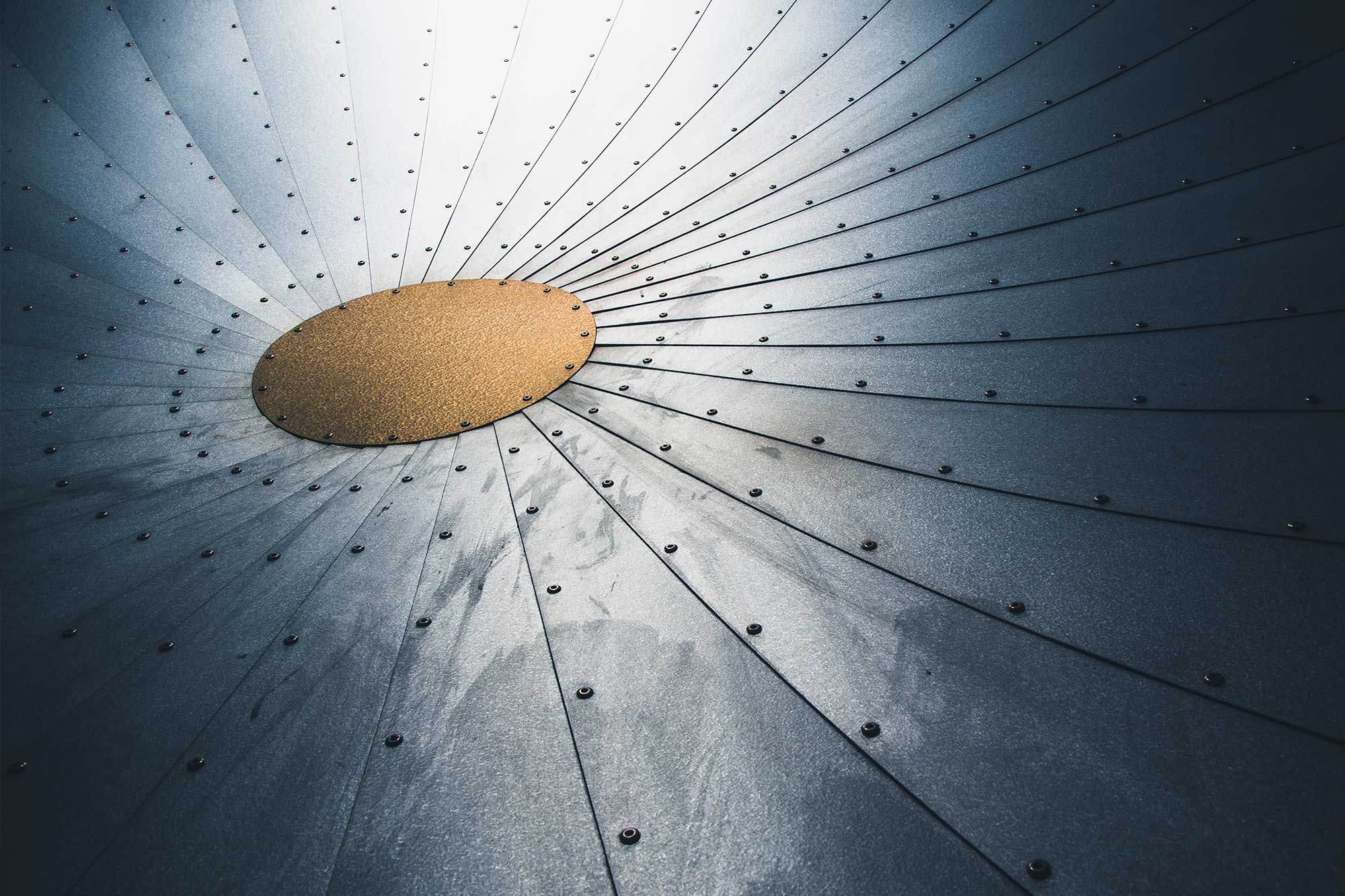

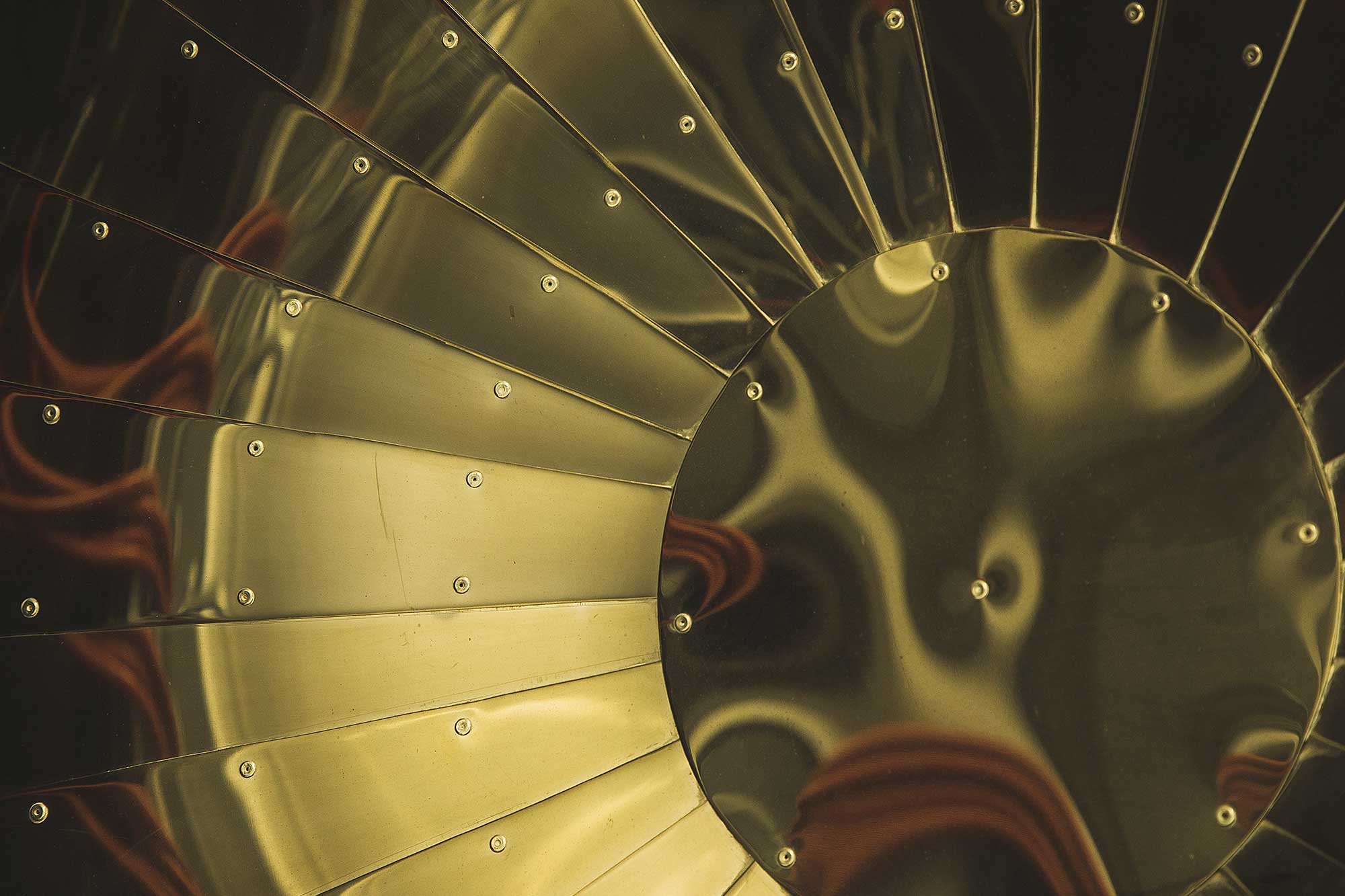

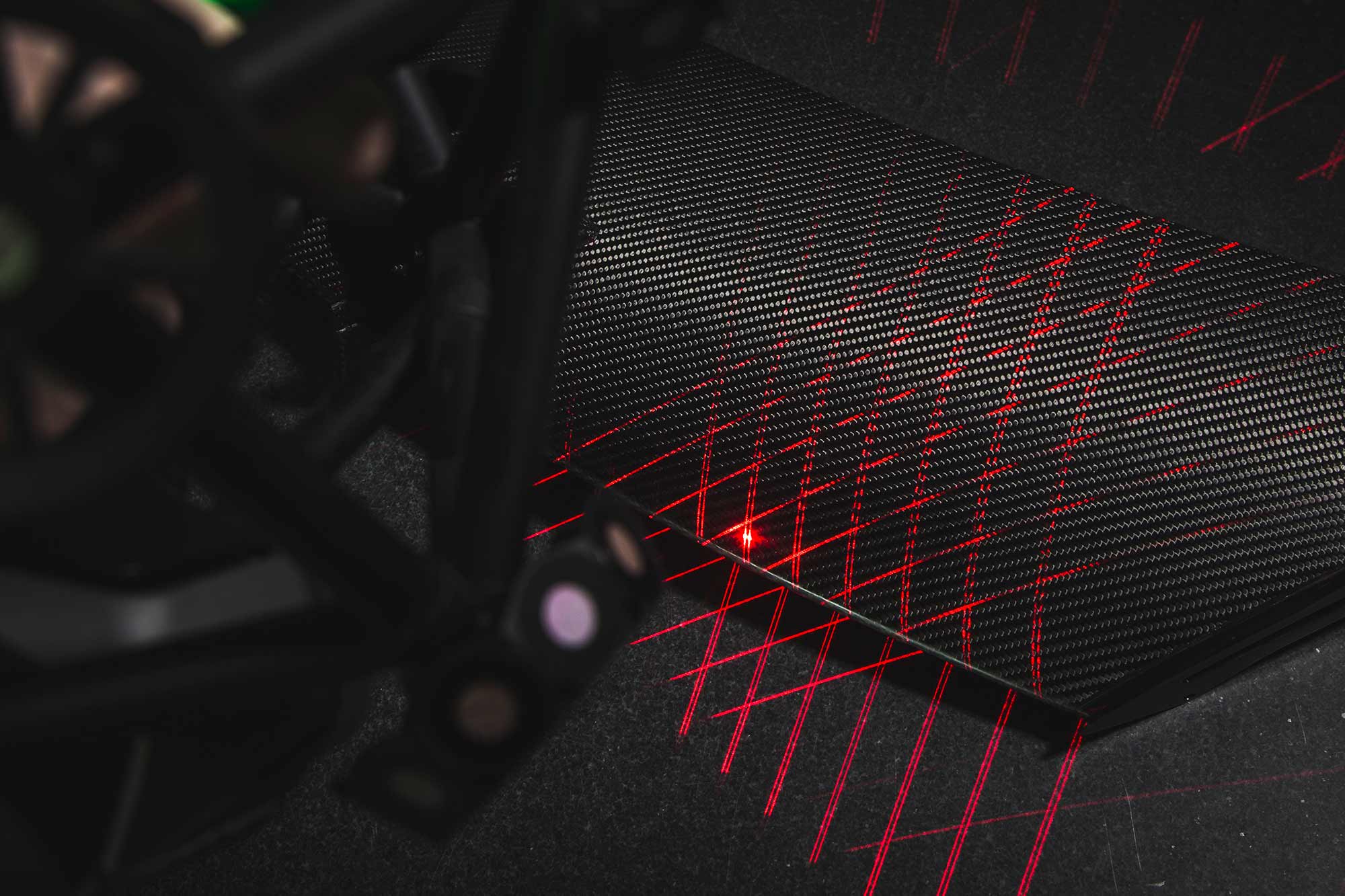

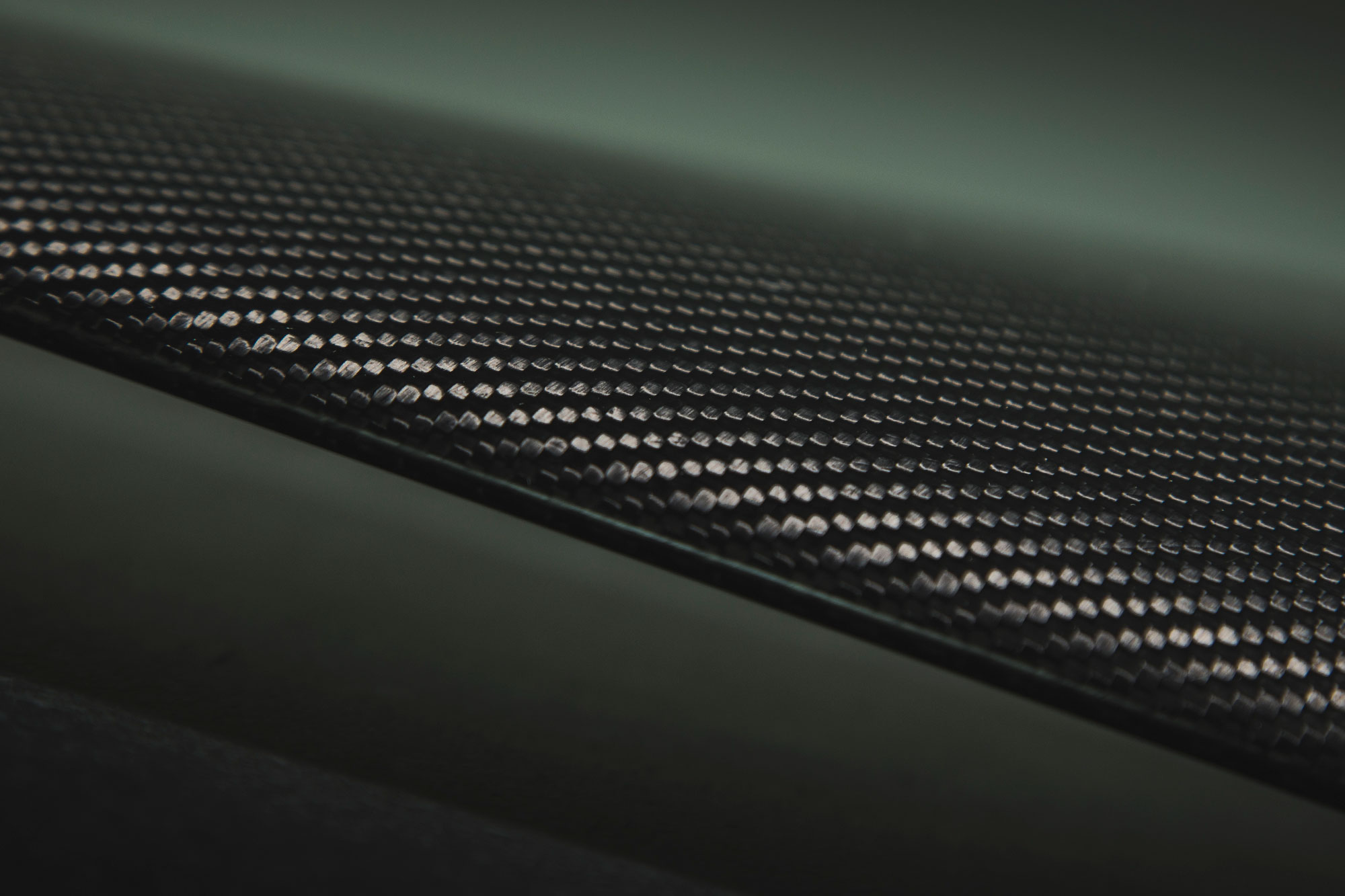

Welcome to the Retrac Group, an established world-class manufacturing specialist, with elite composites and metallics divisions that are a trusted supplier to some of the largest brands in the Automotive, Aerospace, Formula One™ and Motorsport sectors.

retrac productionsretrac composites

Across our two divisions, Retrac Productions Ltd and Retrac Composites Ltd, the Retrac Group offers the complete engineering partnership and forms an extension of our clients’ manufacturing capabilities.

With a 50-year history of innovation and manufacturing excellence, Retrac Group has been a key supplier to more than half the Formula 1 World Champions across the past two decades.

Performance. Precision. Pride. The Retrac Group’s core values drive our complete service, offering a single-entity manufacturing solution with an outstanding reputation for our ability to undertake the shortest possible lead time and still deliver on cost and quality.